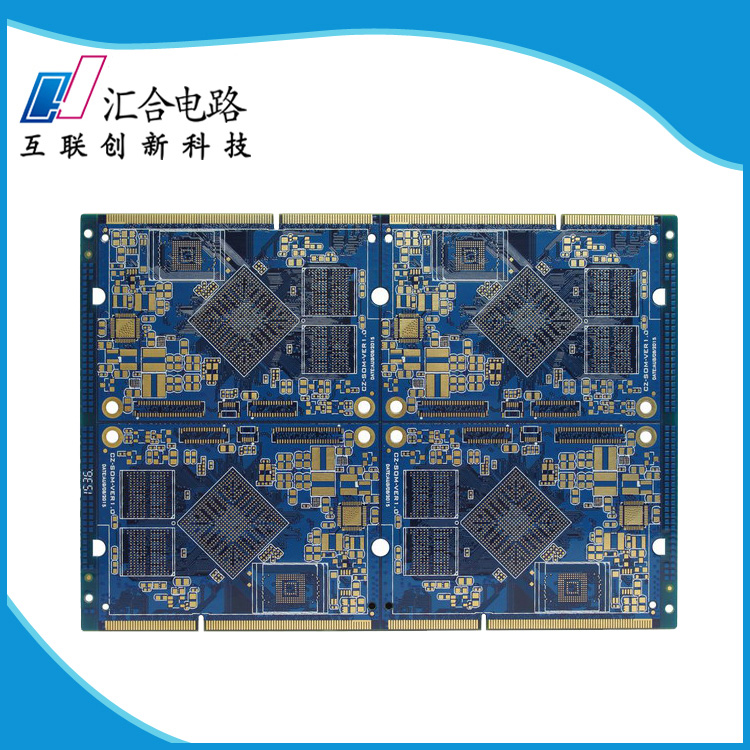

匯合電路是專業(yè)的線路板打樣服務商��,專注于高精密多層板����、特種板的研發(fā)�����,以及pcb打樣和中小批量板的生產(chǎn)制造����。最近許多客戶向我們咨詢:如果PCB選材不一樣����,是否有不良的影響?

首先���,通過線路板打樣出的印刷電路板的信號具有依賴于印刷電路板的介電常數(shù)的速度�����。例如��,當信號頻率超過5 GHz時�����,F(xiàn)R- 4的典型介電常數(shù)(約4.7)下降到接近4����。然而,羅杰斯RO4350材料的相對介電常數(shù)從0到15 GHz是恒定的(大約3.5)�����。如果印刷電路板的介電常數(shù)相對于頻率變化��,那么信號的不同頻率分量將具有不同的速度�����。這意味著�,這些組件將在不同的時間達到負載。結(jié)果�����,這會導致數(shù)字信號的失真�。

Secondly, the signal losses due to printed circuit board material increase with frequency. Again, each harmonic of the digital signal will be attenuated according to that frequency of operation. Increased loss of the signal components will add to the distortion of the digital signal.

????其次,由于印刷電路板材料的信號損失隨頻率增加����。再次,數(shù)字信號的每一個諧波將根據(jù)該操作頻率衰減��。信號分量的增加會增加數(shù)字信號的失真����。所以,線路板打樣的選材會影響線路板質(zhì)量�。

Printed circuit board layout is often the single most important factor affecting the electromagnetic compatibility of electronic systems. Boards that are auto-routed or laid out according to a list of "design rules" do not usually meet electromagnetic compatibility requirements on the first pass; and the products using these boards are more likely to require expensive fixes such as ferrites on cables and shielded enclosures. Taking the time to ensure that components are properly placed and traces are optimally routed will generally result in products that meet all electromagnetic compatibility and signal integrity requirements on time and on budget.

????因為印刷電路板布局往往是影響電子系統(tǒng)電磁兼容性的最重要的因素。根據(jù)“設計規(guī)則”列表自動布線或布置的板通常不滿足第一道次的電磁兼容性要求�����;使用這些板的產(chǎn)品更可能需要昂貴的修復件�����,例如在電纜和屏蔽外殼上的鐵氧體?����;〞r間來確保組件被適當放置�,并且軌跡被最佳路由,通常會導致產(chǎn)品在時間和預算上滿足所有電磁兼容性和信號完整性要求�。這也表明線路板打樣的選材尤為重要。

相關閱讀:影響PCB打樣廠生產(chǎn)電路板可焊性的因素《二》【匯合電路】

?

掃描匯合電路服務號��,更多匯合趣事等你來了解

?

匯合電路服務號

?

掃描匯合電路微信小程序���,獲取更多PCB資訊

?